OEM vs ODM Smartwatch Manufacturing: Which Cooperation Model Is Right for Your Project?

2026-01-19

As demand for elderly smartwatches, GPS tracking wearables, and telecare devices continues to grow, more brands and solution providers are entering the market. However, one of the first strategic decisions every buyer must make is choosing between OEM smartwatch manufacturing and wearable OEM ODM development.

Selecting the right cooperation model directly affects development cost, launch speed, customization flexibility, and long-term scalability. This guide identifies the key differences and helps B2B buyers choose the right path for their project.

What Is OEM Smartwatch Manufacturing?

OEM smartwatch manufacturing builds on an engineered, validated, and certified base platform. As the manufacturer, JiAi Intelligent Technology provides ready platforms targeting elderly care, SOS tracking, and GPS positioning. You add your brand presence while keeping the foundation consistent.

OEM delivers fast, low-risk customization: branding and packaging updates, light firmware adjustments, and cosmetic options like colors and straps. The core hardware, RF, and base firmware are fixed and proven, keeping risk - and surprises - to a minimum. It uses established supply chains and test processes. It also ensures predictable quality and fast fulfillment.

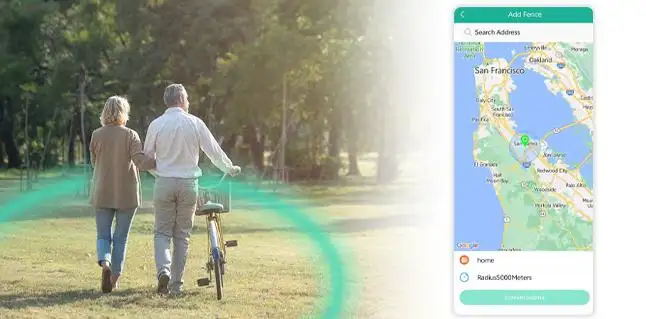

OEM works best when your needs match common use cases. We standardize fall detection, SOS, geofencing, and 4G - then keep variant choices simple so your team iterates quickly rather than reinventing.

When OEM Is the Right Choice

• You need fast time-to-market. Launch in weeks, not months.

• You prefer low development cost. No major NRE or tooling.

• Your requirements match existing functions. No custom PCB required.

• You are testing a new market. Validate demand with low MOQ.

• You want stable, mass-produced models. Proven yield and reliability.

For many telecare service providers, distributors, and private label smartwatch brands, OEM is the practical starting point. You get predictable performance and clear pricing. You also get CE/FCC/RoHS coverage out of the box. JiAi's OEM pipelines include multi-language firmware and robust aging tests for field stability.

What Is ODM Smartwatch Development?

ODM smartwatch development means true customization. You start with requirements. We translate them into industrial design, mechanical design, and custom PCB layout. We pick sensors and modules that match your health metrics, GPS accuracy needs, and battery life goals. We then adapt firmware features, app logic, and cloud APIs to your platform.

As an experienced ODM smartwatch supplier, JiAi supports end-to-end custom smartwatch development. This includes ID concepts, DFM/DFX reviews, BOM optimization, antenna tuning, and operator-specific LTE band work. From EMC and SAR to carrier acceptance, the regulatory path is planned end-to-end. We handle the regs - EMC, SAR, plus carrier approvals. ODM lets you stand out with custom protocols, safety workflows, and caregiver dashboards that match how your team actually works.

When ODM Is the Right Choice

• You want a device that looks and feels uniquely yours. Custom ID/MD and molds.

• Your platform requires custom data protocols. Secure, documented APIs.

• You want exclusive product ownership. IP alignment and ODM agreement.

• You target specific certification or carrier bands. Tailored RF design.

• You plan long-term brand growth. Roadmaps and feature evolution.

For established telecare operators, healthcare solution providers, and IoT platform companies, ODM unlocks innovation. You control experience, features, and ecosystem fit. You generate competitive barriers and fortify brand equity.

OEM vs ODM: Key Differences at a Glance

• Development Time: OEM 2 - 6 weeks; ODM 3 - 6 months with scope variation.

• R&D Cost: OEM low; ODM medium - high due to design and validation.

• Customization: OEM keeps it simple; ODM lets you build it your way - hardware and firmware included.

• Ownership: With OEM, the manufacturer owns the core; with ODM, you own it if the contract says so.

• Branding: OEM does logos and colors; ODM shapes the whole look and feel.

• Certification: OEM relies on current approvals; ODM goes through new testing.

• MOQ: OEM lower; ODM medium - high based on tooling and materials.

• Differentiation: OEM moderate; ODM high, defensible differentiation.

How JiAi Intelligent Technology Supports Both Models

JiAi Intelligent Technology specializes in elderly smartwatches, GPS trackers, and telecare wearables. We run parallel OEM and ODM workflows to match your project stage.

For OEM smartwatch manufacturing, we maintain pre-certified platforms with multi-language firmware and reliable supply. We provide quick brand customization, packaging design, and firmware parameter tuning. Most projects dispatch samples within days and enter mass production through short, reliable cycles.

For ODM custom smartwatch builds, our team runs the program end-to-end. We oversee requirement mapping, ID/MD creation, PCB design, RF optimization, firmware and app adaptation, cloud API linkage, and pilot builds. We book certification planning early to keep risk in check. DFM-driven reviews boost yield and reduce unit cost. You scale on a reliable EVT - DVT - PVT track.

It isn't just engineering - we run a tight factory: incoming inspection, long burn-in tests, environmental qualification, and full traceability. We keep your roadmap safe with NDAs and a plan you can track. Start OEM to test demand; move to ODM after specs and volumes are agreed.

Typical Buyer Scenarios

• Scenario 1: Telecare Service Provider

Rolling out a city program fast? Use OEM to get devices in the field quickly; once the program proves out, shift to ODM to fine-tune design and costs. You pick OEM to meet timeline gates, utilize SOS/geofence, and preserve budget discipline.

• Scenario 2: IoT Platform Company

Your cloud stack depends on a custom data model and hardened security. Select ODM to deliver security-first APIs, tuned firmware, and the right LTE band approvals - while keeping full design ownership for long-term growth.

• Scenario 3: Retail Brand

If your brand needs a premium smartwatch with a signature silhouette, ODM delivers tailored ID, luxury finishes, and a consistent brand language.

• Scenario 4: Regional Distributor

Pilot via OEM with minimal MOQs to validate; transition to ODM for custom SKUs, stronger positioning, and better profit per unit.

FAQ

Q: Can OEM migrate to ODM?

A: Yes. Validate quickly with OEM, then step up to ODM for deeper customization and design IP ownership.

Q: Who owns ODM designs?

A: The client - custom hardware, firmware, and molds are owned per the ODM contract.

Q: Supported certifications?

A: OEM: CE/FCC/RoHS already in place. ODM: plan-in SAR, EMC, reliability, and operator approvals.

Q: What are typical MOQs?

A: OEM MOQs are lower to facilitate pilots. ODM MOQs are higher to account for tooling, materials, and certification spend.

Q: How long is the lead time?

A: OEM samples in days; 2 - 6 weeks to production. ODM usually takes 3 - 6 months from spec lock to mass production.

Q: Do you support data security and platform integration?

A: Yes. We support secure firmware, encrypted communications, and documented API integration with your cloud stack.

Conclusion

Choose OEM for speed and low risk; choose ODM for lasting differentiation. JiAi Intelligent Technology enables an OEM-to-ODM journey, offering one-stop solutions for elderly care, GPS tracking, and telecare wearables so you can launch fast and scale with confidence.